September 22, 2017

I think I’ve mentioned before that it has been a once-in-a-lifetime opportunity to work with an amazing artist and sculptor on their net zero, passive house. We took the day to visit the site in New Jersey and it was thrilling to walk through these spaces that as complicated as they were in 2D, I was able to create the 3D visualization in my head to successfully build a set of construction drawings. But there is nothing like walking through the actual spaces that now physically exist.

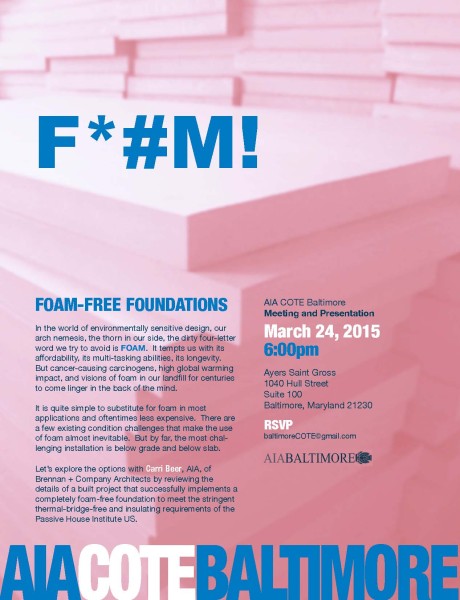

So many great things happening with this project – foam-free and net zero; perlite under slab; pre-manufactured wall trusses as the insulation cavity; low-cost, DIY construction techniques; and creative use of color and material.

I can’t forget to add the experience of exceptional lunches from the garden with every visit!